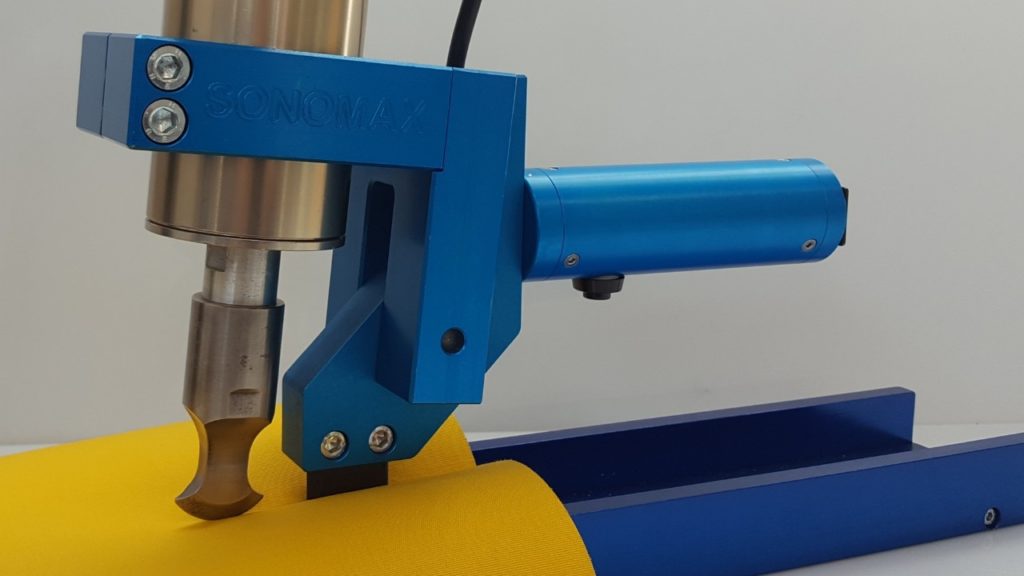

Sonomax manual ultrasonic cutting systems are ideal for cutting and welding synthetic or partially synthetic fabrics simultaneously, in both straight and curved sections, precisely and without fraying.

This ultra-low energy technology uses vibrations and, unlike a hot system, does not require heating and cleaning time for the cutting blade, resulting in perfectly clean, even and burn-free edges.

These manual ultrasound systems can be of different frequency (30-40 Khz), power, amplitude and weight, are combined with SX series generators and have interchangeable sonotrodes to perform different types of cutting.

Frequencies: 30-40 kHz

Ideal for linear cuts, the manual cutting frame is designed to be guided freely on a rail by manually pushing it in the desired direction without applying any pressure to the fabric.

The structure is pre-tensioned and does not require any adjustment.

Frequencies: 30-40 kHz

Frequencies: 30-40 kHz

Lascia un recapito.

Ti ricontatteremo al più presto!