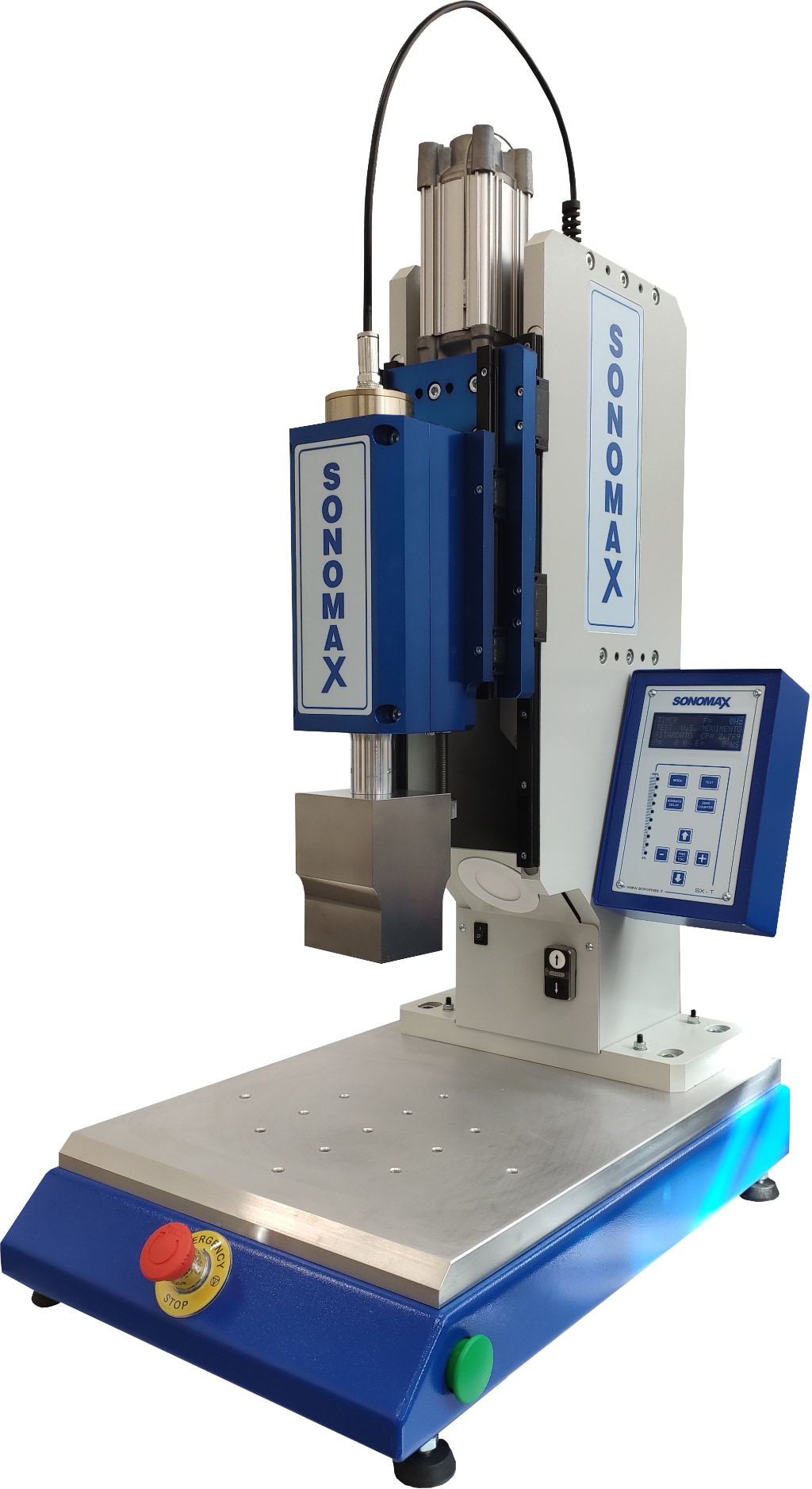

Frequency: 20 kHz

Power: 1500-2500 W

Tension: 230 V, on request 115-240 V

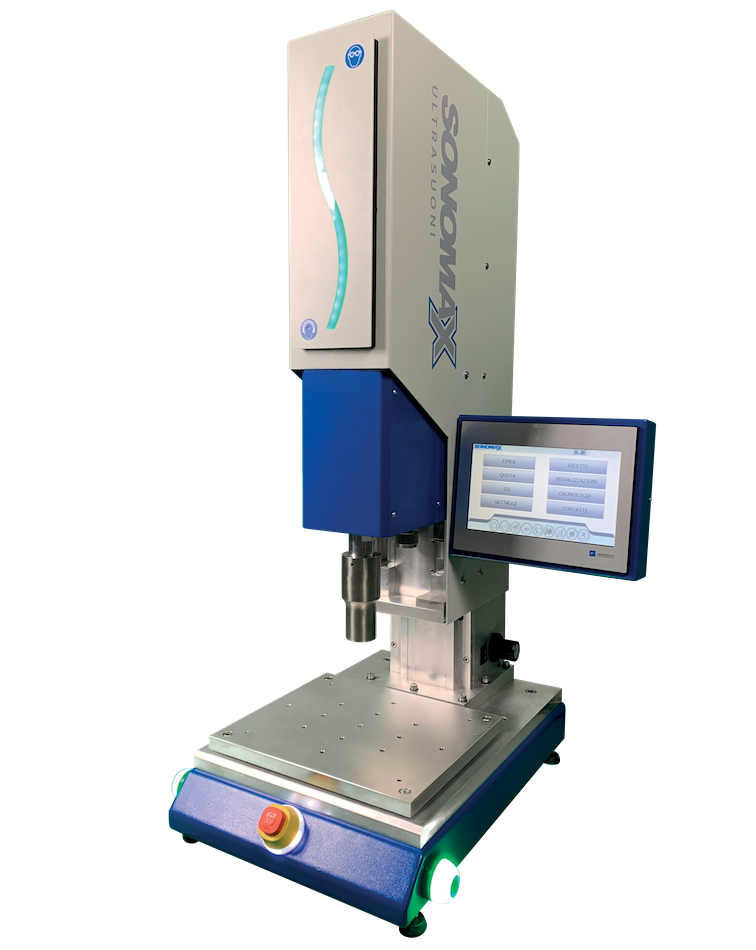

Frequency: 20 kHz

Power: 1500-3000 W

Tension: 230 V, on request 115-240 V

11" touch display

Download the data sheet

Frequency: 30 kHz

Power: 800-1200 W

Tension: 230 V, on request 115-240 V

Display Touch 11"

Foto in aggiornamento

Frequency: 30 kHz

Power: 800-1200 W

Tension: 230 V, on request 115-240 V

Display Touch 11"

Frequency: 35 kHz

Power: 700-1000 W

Tension: 230 V, on request 115-240 V

Display Touch 11"

Foto in aggiornamento

Frequency: 35 kHz

Power: 700-1000 W

Tension: 230 V, on request 115-240 V

Display Touch 11"

Frequency: 40 kHz

Power: 400-600 W

Tension: 230 V, on request 115-240 V

11" touch display

Foto in aggiornamento

Frequency: 40 kHz

Power: 400-600 W

Tension: 230 V, on request 115-240 V

11" touch display

Lascia un recapito.

Ti ricontatteremo al più presto!