The ultrasonic welding of thermoplastic materials represents a key technology for the production of devices medical high-precision, sterilisable and safe. This process, free of glues or solvents, guarantees hermetically sealed and mechanically resistant joints, meeting the most stringent requirements of the sanitary sector.

What is ultrasonic welding in the medical sector?

The ultrasonic welding is a thermoplastic joining technique that utilises high-frequency mechanical vibrations (typically between 20 kHz and 40 kHz) to fuse two plastic surfaces through internal friction. In the context of medical and biomedicalIt is used to assemble disposable components, protective casings, diagnostic devices and biocompatible equipment parts.

The most commonly used materials include polycarbonate, polypropylene, polyethylene, ABS, nylon e polystyreneall perfectly compatible with the ultrasonic process and frequently used in the production of plastic components for the medical sector.

How the process works

The process of ultrasonic welding takes place in a few highly controllable steps:

- Component positioning: the two parts to be welded are inserted into a support mask tailor-made.

- Sonotrode application: a customised sonotrodewith geometry designed according to the workpiece, makes contact with the surface to be welded.

- Vibration generation: the ultrasound generator converts electrical energy into high-frequency mechanical vibrations.

- Localised fusionmolecular friction heats the material to melting point.

- Coolingpressure is maintained to ensure a solid and even joint.

The process is completely automatable and takes less than one second per cycle.

Advantages of ultrasonic welding in the medical sector

In the medical sector, the ultrasonic welding offers a combination of advantages that are difficult to match with other joining methods (glue, laser, direct heat):

- Hygienic safetyabsence of solvents or chemical contaminants.

- SpeedVery fast cycles, perfect for mass production of disposable devices.

- Hermetic junctionfundamental for diagnostic devices e sterile containers.

- Compatibility with sterilisationSuitable for processes such as autoclave, gamma rays, ethylene oxide.

- Quality controleasily integrated with on-line quality monitoring.

Concrete industrial applications

Ultrasound technology is now essential in many applications in the industry medical e biomedicalincluding:

- Filters and valves for respirators

- Rapid diagnostic cassettes

- Components for syringes, catheters, needles

- Containers for collecting biological samples

- Components for infusion and haemodialysis devices

- Enclosures of portable electronic devices

All these products require precise, stable welding that is compatible with the highest safety standards.

Technical requirements: machines, frequencies, powers

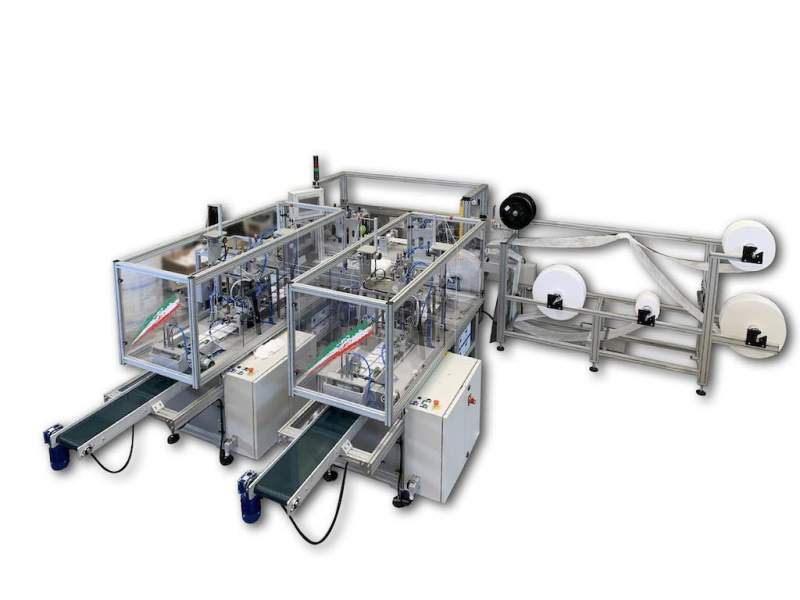

Le Sonomax ultrasonic welders for the medical sector are designed to operate in highly critical environments:

- Available frequencies: 20 kHz for more robust components, 30-35-40 kHz for small elements and delicate materials.

- Variable power: from 400 W to beyond 3000 Wdepending on the geometry of the workpiece and the type of material.

- Integrated digital controltouch panels, recipe management, saving parameters.

- Interface with PLCs and robotsready for integration into automated production lines.

- Cleanroom versionsmodels available with coatings and materials compatible with sterile environments.

Reference regulations and standards

Sonomax assists customers in process validation and in the documentation required to obtain certifications.

Sonomax: the partner for medical welding in Italy and Europe

With over 20 years of experience, Sonomax Srl is the benchmark for ultrasonic welding in the industry medicalthanks to:

- Dedicated technical consultancy for choosing the most suitable solution

- Prototyping and sample testing at the in-house laboratory

- Development of customised sonotrodes

- Direct after-sales service, fast and specialised

- Technical training for operators, maintenance and quality managers

Each Sonomax welder is designed and manufactured in Italy with attention to detail, guaranteeing industrial reliability e regulatory compliance.

Frequently asked questions (FAQ)

Are ultrasonically welded products sterilisable?

Yes. Joints made using ultrasonic technology resist sterilisation processes.

Which plastics are compatible?

The most common are polycarbonate, polypropylene, polyethylene, ABS, nylon e PSall widely used in the health sector.

Is it possible to test samples before purchase?

Yes. The Sonomax laboratory is equipped to carry out free tests on prototypes or limited series.

Are Sonomax machines compatible with cleanroom environments?

Absolutely. We have models designed for sterile environments.

What is the difference between 20 kHz and 40 kHz?

Lower frequencies (20 kHz) are suitable for large or resistant components, higher frequencies (35-40 kHz) for delicate medical components or small.

Do you have a project in the medical sector and are you looking for a safe, fast and efficient solution?

Contact Sonomax today for a tailor-made consultation and a free welding test in our technical laboratory.