The ultrasonic welding of thermoplastic materials is an advanced, fast and sustainable joining technology, ideal for the realisation of new-generation packaging in the field food, cosmetic, pharmaceutical, technical-industrial e green packaging.

Thanks to its ability to generate localised heat through high-frequency mechanical vibrations, this process allows plastic materials to be joined without glues, solvents or electrical resistances, ensuring hygienic, aesthetically clean and energy-efficient seals.

Sonomax Srlwith over 20 years of experience in the design of ultrasonic weldersis the ideal partner for those seeking precision, speed and environmental compatibility in the production of packaging.

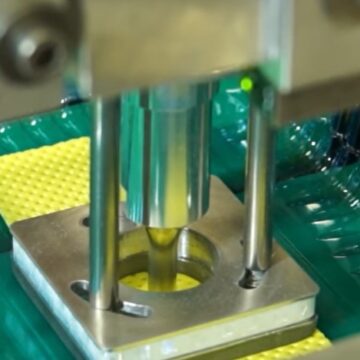

How ultrasonic welding works

The process takes place through transformation of electrical energy into high-frequency mechanical vibrations (20-40 kHz), transmitted by a sonotrode to the contact zone between two thermoplastic surfaces. The vibrations generate a heating by molecular frictionby locally melting the materials. Once the vibrations stop, the joint cools under pressure, generating a strong, clean and durable weld.

Everything happens in very few secondsmaking the technology perfectly integrable into high-productivity automatic packaging lines.

Benefits for packaging

Compared to traditional methods (heat sealing, adhesive bonding, hot bonding), ultrasonic welding guarantees:

- Absence of glues, resins or solvents → ideal for food and cosmetic use

- Extremely low cycle speed

- Reduced energy consumption and low environmental impact

- Visually clean welds without burrs or burn marks

- High repeatability and easy quality control

- Compatibility with traditional and innovative materialsincluding compostables

Main applications

Food packaging

A sector where hygiene, resistance and speed are essential. Examples:

- Single-dose sticks for honey, ketchup, sauces, syrups

- Vertical and horizontal envelopes for snacks, dried fruit, frozen food

- Coffee capsules in plastic

- Heat-sealed caps and hook-and-loop fasteners

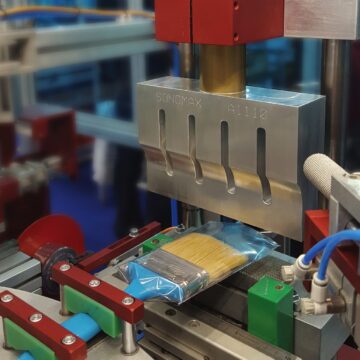

A popular technique is the tuftingthe 'tufted' sealing of pack ends: it improves the aesthetics and functionality typical of single-serving sachets, snacks or textile reels.

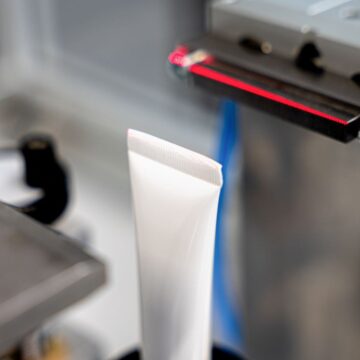

Cosmetic packaging

Applications where aesthetic precision and content security are paramount:

- Cream or lotion tubes

- Disposable skincare mini-portions

- Stick for gel products or serums

- Vials, capsules and sachets

Pharmaceutical packaging

Ultrasound ensures sterile, certified and repeatable welds, ideal for:

- Single-dose supplements

- Medical-food sachets

- Oral gels, eye drops, disinfectants

- Sterile ampoules and containers

Technical-industrial packaging

Packages requiring robustness, traceability and compatibility with special materials:

- Protective envelopes for electronic components

- Automated packaging of small parts

Sustainable and bioplastic packaging

More and more companies are choosing compostable or recyclable materials as an alternative to traditional plastic. The Sonomax ultrasonic welders are compatible with numerous thermoplastic bioplastics as:

- PLA (polylactic acid)

- PBS, PCL, starch blend

- Single-material film low-barrier

Thanks to the precise control of parameters and the availability of different frequencies (20-30-35-40 kHz), Sonomax makes it possible to achieve quality welds even on delicate materialsresponding to the needs of green packagingcompostable or recyclable, without compromising on efficiency or aesthetics.

Technical Requirements and Supported Materials

Le Sonomax ultrasonic welding machines operate with:

- Frequencies20 - 40 kHz

- Available powers400 to 3000 W

- Weldable materials:

- Polypropylene (PP)

- Polyethylene (PE)

- PET, PS, PLA, PBS

- Multilayer and barrier film

- Compostable bioplastics

Each machine can be configured with customised sonotrodes, intuitive HMI interfaces, quality control modules, Industry 4.0 integration e real-time monitoring of parameters.

Sonomax Srl: Italian technology for modern packaging

Sonomax Srl designs and manufactures complete ultrasonic welding solutions for plastics and bioplastics in Italy, offering:

- Bench and compact welders

- High-frequency digital generators

- Customised systems for industrial automation

- Aesthetic tufting solutions

- Technical support, training, free laboratory tests

Each project is designed according to packaging type, material and production volume, ensuring maximum efficiency, reliability and integration into the customer's processes.

Frequently asked questions (FAQ)

Can I weld compostable materials such as PLA?

What is tufting?

Is ultrasonic welding suitable for food use?

Do you have a laboratory to test my materials?

Is it possible to integrate your machines into an automated line?

For more information, visit the pages dedicated to digital ultrasonic generators and the packaging weldersor contact us for customised technical advice on your project.