The ultrasonic welding and cutting today represent one of the most reliable, clean and efficient technologies for the processing of thermoplastics in technical textiles and personal protective equipment (PPE). This method is based on the transmission of high-frequency vibrations that generate localised heat, melting the materials and allowing a precise and durable bond or a clean, sealed cut, without the need for glues, solvents or mechanical elements.

How ultrasonic welding and cutting works in technical textiles

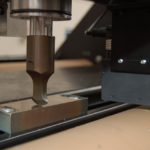

The process uses a sonotrodea component that vibrates at a very high frequency (usually between 20 and 40 kHz) and applies these vibrations to a specific surface of the material. The molecular friction produced generates enough heat to melt polymers thermoplastics in the fabric, without damaging its surface. The melted zone solidifies rapidly under pressure, creating a continuous jointdurable and waterproof.

In the case of the ultrasonic cutting, the same technology is applied to dissect the material while simultaneously sealing the edges, avoiding fraying, fraying or the need for additional stitching or beading.

Advantages over other joining methods

The ultrasonic welding for textiles and PPE offers numerous advantages over traditional methods such as sewing, gluing or heat sealing:

- No needles, threads or gluesreducing production time and material costs.

- Hermetic sealingideal for applications requiring protection from dust, liquids or pathogens.

- High execution speedwith very fast cycle times (fractions of a second).

- Clean cutwithout fraying.

- Repeatable and controllable processsuitable for automated and in-line production.

- Reduced thermal impact on the surrounding materials, which maintains the mechanical and functional properties of the fabric.

Industrial applications

Ultrasonic technology is particularly suitable for the processing of technical fabrics made of synthetic fibres or blends containing thermoplastic components. Main applications include:

- Surgical masks and FFP2/FFP3

- Protective overalls and disposable gowns

- Non-woven fabric (TNT) filters

- Fireproof or high-visibility clothing

- Technical automotive fabrics (interior trim, airbags, soundproofing)

- Waterproof bags, backpacks and technical textiles

- Covers for medical and sterile devices

In all these areas, ultrasonic welding guarantees high standards of safety, hygiene and durabilityindispensable for professional employment.

Technical requirements: machines, frequencies and powers

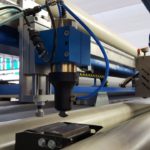

Le ultrasonic welding and cutting machines intended for the textile sector can be manual, semi-automatic or fully automated, depending on production requirements.

Operating frequencies generally vary between:

- 20 kHzideal for thicker and more structured materials

- 30 kHz, 35 kHz or 40 kHz, for lighter, delicate fabrics and precision applications

Powers can range from 400 W up to 2000 Wdepending on the type of weld, the desired strength and the number of layers to be joined or cut.

You can choose between:

- Bench weldersfor manual operations on small series or prototyping

- Units that can be integrated into automatic linesfor continuous production

- Roller machines for continuous welding

All Sonomax solutions are compatible with the main thermoplastics used in technical textiles, including: polyester, polypropylene, nylon, PVC and TNT (non-woven fabric).

The answer from Sonomax Srl

With over 20 years of experience in the field of ultrasonic welding for thermoplastics, Sonomax Srl is a reference point for European companies active in the production of IPR, technical clothing, industrial filtration and other highly regulated sectors.

Sonomax offers:

- Design and production of customised welding machines for the textile sector

- Technical consultancy for integration into existing lines or development of new processes

- Training and after-sales service in Italian and European languages

- Original spare parts, customised sonotrodes and high reliability components

The Sonomax product range includes:

- Ultrasonic generators high performance

- Column or articulated arm welders

- Modular units for industrial automation

- Rotary cutting and sealing systems for textiles

- Customised sonotrodes for complex geometries

Each solution can be adapted to the specific requirements industry, in accordance with current regulations and the demands of the European market.

Frequently asked questions (FAQ)

Which materials can be ultrasonically welded or cut in the textile industry?

Mainly thermoplastic materials such as TNT, polyester, polypropylene, PVC, nylon, also in multilayer or laminated form.

Is ultrasonic welding safe for the environment?

Yes. It does not require the use of glues, solvents or chemical adhesives, and is therefore an environmentally friendly process with no harmful emissions.

How long does ultrasonic welding last?

Is it possible to cut and weld at the same time?

Yes. With ultrasonic technology it is possible to cut and weld in a single pass, saving time and ensuring finished edges.

Does Sonomax offer support for the development of new IPRs?

Absolutely! Our technical team works together with designers and manufacturers to optimise processes and produce innovative and compliant products.

To learn more, visit the page dedicated to our cutting machines or request a personalised technical consultation.